Quality-Centric Watch Manufacturing

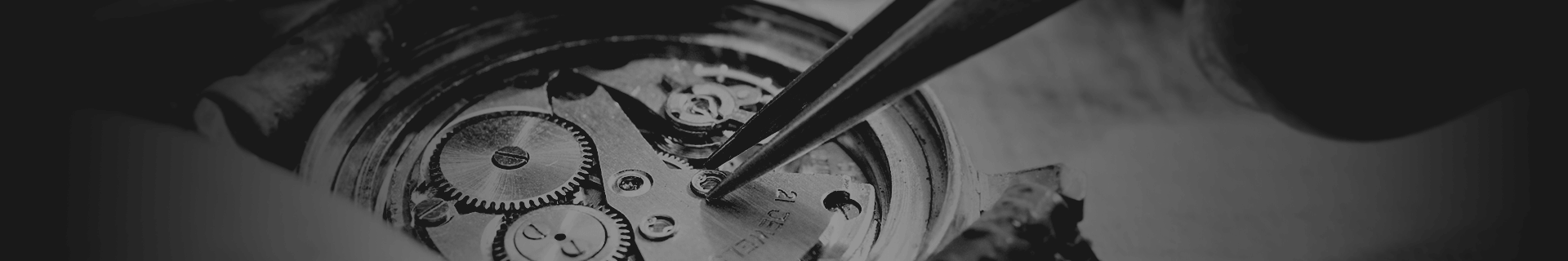

THE QUALITY OF OUR PRODUCTS AND SERVICES IS OUR TOP PRIORITYAs an independent watch manufacturer, we perform rigorous inspections during all stages of the manufacturing process to ensure total integrity of all materials used and an end product of consistently high quality and optimum functionality.

Before any watch is dispatched from our facility, it is checked for accuracy, reliability and water resistance by one of our engineers, according to our strict guidelines. A computer controlled air pressure device is used to check for water resistance. This process detects any leak and the level of water resistance of the watch is determined.

Wolf King implements a Total Quality Management (TQM) methodology - a strategy in which all members of an organization participate in improving products, services, and organizational processes. TQM has been successfully applied in manufacturing, education, government, and service industries, as well as NASA space and science programs. TQM provides an umbrella under which the efforts of everyone in an organization is geared toward success through customer satisfaction.Montrihard

- TQM is composed of three paradigms:

- • Total: the entire organization is involved

- • Quality: at all levels and all processes

- • Management: at all the steps such as Planning, Organizing, Controlling, Leading, provisioning

TQM generally starts by sampling a random selection of the product to ensure integrity. Then, the sample is further tested for issues that matter most to the end users.

During this process, the causes of any failures are isolated and secondary measures are designed to correct them. In fact, after TQM has been implemented it’s very common for parts to be redesigned, resulting in a better end product for users and lower manufacturing costs.

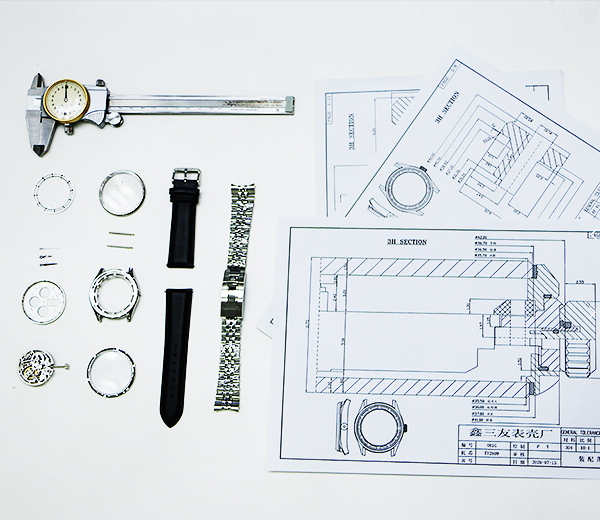

Incoming Component Management & Inspection

Each watch is composed of over one hundred components. Managing a large number of parts & controlling their quality is the type of work that requires expertise.

Wolf King, with a professional team of sourcing staff, we ensure that all components from our subcontractors meet the environmental standards & regulations of your country & region.

All incoming components are classified & inspected in our IQC department according to the requirements listed on the design drawing before being put into mass production.

In-Process Quality Control Accompanies Each Step

Every 20 watch cases, after cutting, are carefully measured with a caliper to ensure the dimensions are consistent with the design.

The diameter and depth of each watch hole are measured with a dial gauche to make sure the size difference is kept within 0.01 mm.

After polishing, every watch case is meticulously inspected by our QC staff to make sure it's scratch-free & well-shaped.